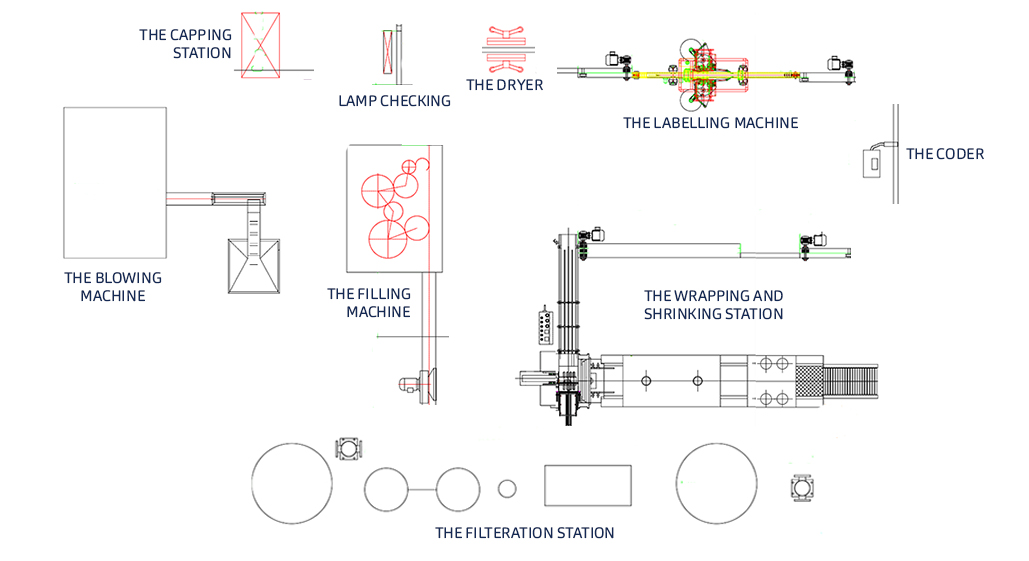

OUR PLANT

FOR MORE INFORMATION PLEASE HOVER OVER THE TEXT OF THE RESPECTIVE MACHINE / STATION*

THE CAPPING STATION

The source of all the bottle caps that are fed to filling machine, using a powerful blower to use air to push all the caps up to a significant height, where they are held, before gravity can gently bring them down in order. Has the capacity to hold a large number of caps and can be adjusted to different cap sizes.

THE DRYER

The Six-Door dyer carefully ensures that the bottles are perfectly dry by the time they leave and is designed to be temperature controlled and power efficient. It also sanitizes the bottles whilst ensuring the oxygen content of the water is not compromised through the raised temperature.

THE BLOWING MACHINE

THE CODER

The Coder imprints the date of manufacture, the date of expiry, and the batch number onto each individual bottle.

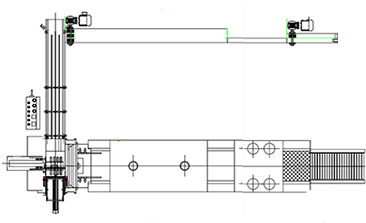

THE WRAPPING AND SHRINKING STATION

The final part of the process, the Wrapping and Shrinking station wraps the bottles as per the required configurations, which can be adjusted, covering them in a resistant plastic film that is shrunk for maximum ergonomic value.

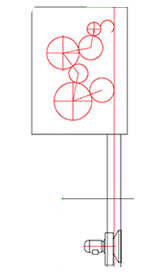

THE FILLING MACHINE

The core of the factory, this is where the bottles are rinsed, filled, and capped. The bottles are fed into the conveyor system and turned upside down- clean sterile water is flushed in at a high pressure and angle, thereby ensuring every inch of the bottle is cleaned. The water is completely removed when the pure and filtered water from the filtration system is pumped in and the bottles are capped. The entire machine is kept in a self contained sterile environment with glass doors sealing and preventing any possible contamination.

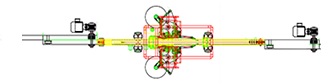

THE LABELLING MACHINE

The Automatic labeling machine wraps and attaches the specific Jalaya Burhani Label onto the bottle, and can be adjusted to a multitude of custom bottle shapes, and custom labels. Specialized carbon brushes ensure the label is stuck on firmly and that no dust or debris is present on the bottles.

FILTERATION STATION

Containing two different tanks for Quartz Sand and Activated carbon, as well as a few other processes, the filtration station is the heart of the factory and contains separate tanks for Raw and Pure water, as well as separate pumps. All of the water is passed through Sterile Stainless Steel pipes to ensure that it is as clean and pure as possible

PLEASE NOTE THE ABOVE IS NOT EXHAUSTIVE